The food processing business needs to handle many painstaking tasks. From production to packaging and dispatching the food, all the tasks should be handled carefully. With the automated process and comprehensive view of all essential operational tasks, the functions of the food processing industry can be managed efficiently.

Microsoft Dynamics presents the dynamics tools for food and beverage companies to meet quality and compliance standards. It allows the customer to manage stock and meet customer demand while maintaining excellent customer service. Let’s look at the prime reasons to choose Microsoft Dynamics for the food processing industry.

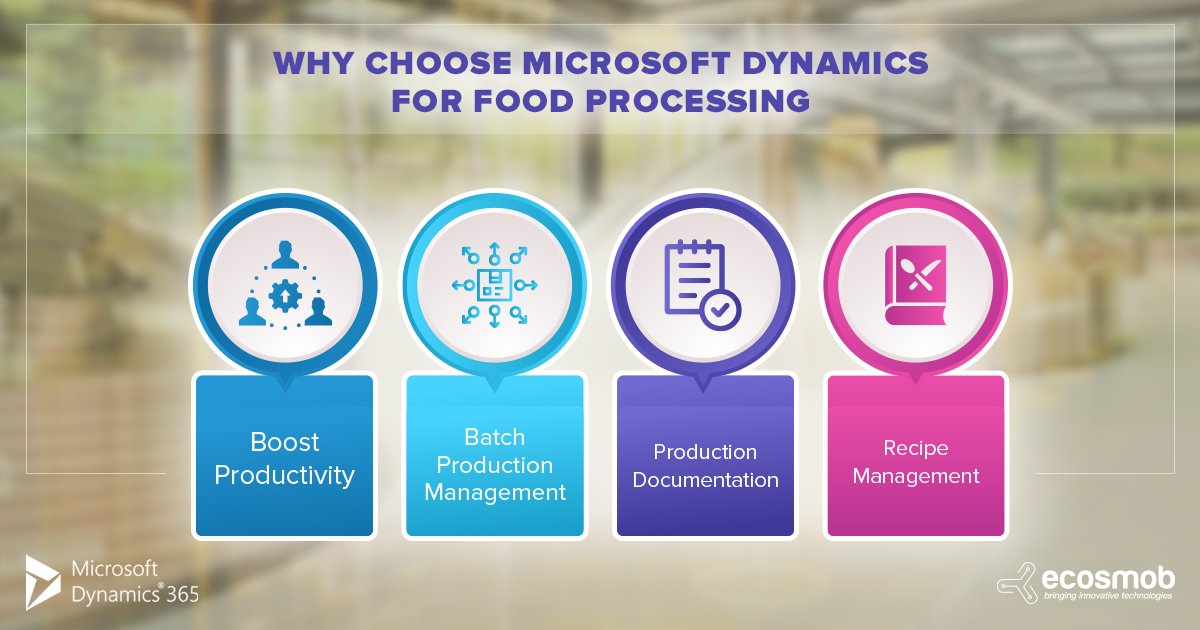

Boost productivity

Microsoft Dynamics system allows going beyond stand-alone business applications with relevant solutions that drive business process automation and employee productivity. By using the system, your entire team can stay connected with the key business data like counts production material, customer data, product materials, and order status. Alos with a single point of communication across the calendar, email, files, collaboration tools, and business processes, you can quickly get insights to improve the productivity of your food business.

Batch production management

The system allows you to automatically calculate intermediate product demand based on production orders for finished goods. Besides, you can schedule production to match delivery requirements and sequence batches for the best use of allocated equipment, and rely on forward and backward traceability to measure and maintain batch quality.

Production documentation

With Microsoft Dynamics, you can record and review all the production data before posting, assuring that raw materials, packaging, and intermediate inventories will be allotted correctly and promptly and that properly finished raw materials become available for production.

Recipe management

For your single- and multi-level recipes, you can dynamically size food processing batches that consolidate your preferred units of volume for ingredients, process directions, or other values. Microsoft Dynamics solution also benefits you to manage the production and costing of co-products and by-products from single or multiple inputs.

Moreover, Microsoft Dynamics for food processing supports your quality goals by allowing you to track lots forward and backward via the production process. Alliance with food quality control supports the acquiescence of your manufacturing with the applicable governmental and industry standards and regulations. Also, you will get a full update regarding the supply and demand for finished goods to create timely production orders and meet the customers’ demand. The inventory management and supply chain management is no longer a complex process with the Dynamics solutions.

More precisely, you will able to handle the following actions with Microsoft Dynamics for Food processing;

– Recipe Management

– Formula Creation

– Nutritional Labelling

– Ingredient Statement and Reporting

– Sample Testing

– Potency Management

– Vendor Management

·

– Inventory Management

– Production Costing

– Lot Tracking

– Master Production Scheduling

– Material Requirement Planning

– Demand Forecasting

– Procurement

– Distribution

– Marketing and sales

– Quality Assurance

– Quality Control

– Corrective and Preventive Action

Do you want to get Microsoft Dynamics solutions for your food processing business?

Connect with us now! Ecosmob is the certified partner of Microsoft that offers a customized yet innovative solution to efficiently control the entire food processing management. From understanding the core business functionality to gathering requirements, our Microsoft consultants will proactively work with you until the deployment of the system. Also, we provide post-deployment services to troubleshoot technical complexities.